Rapid Ramp NH3

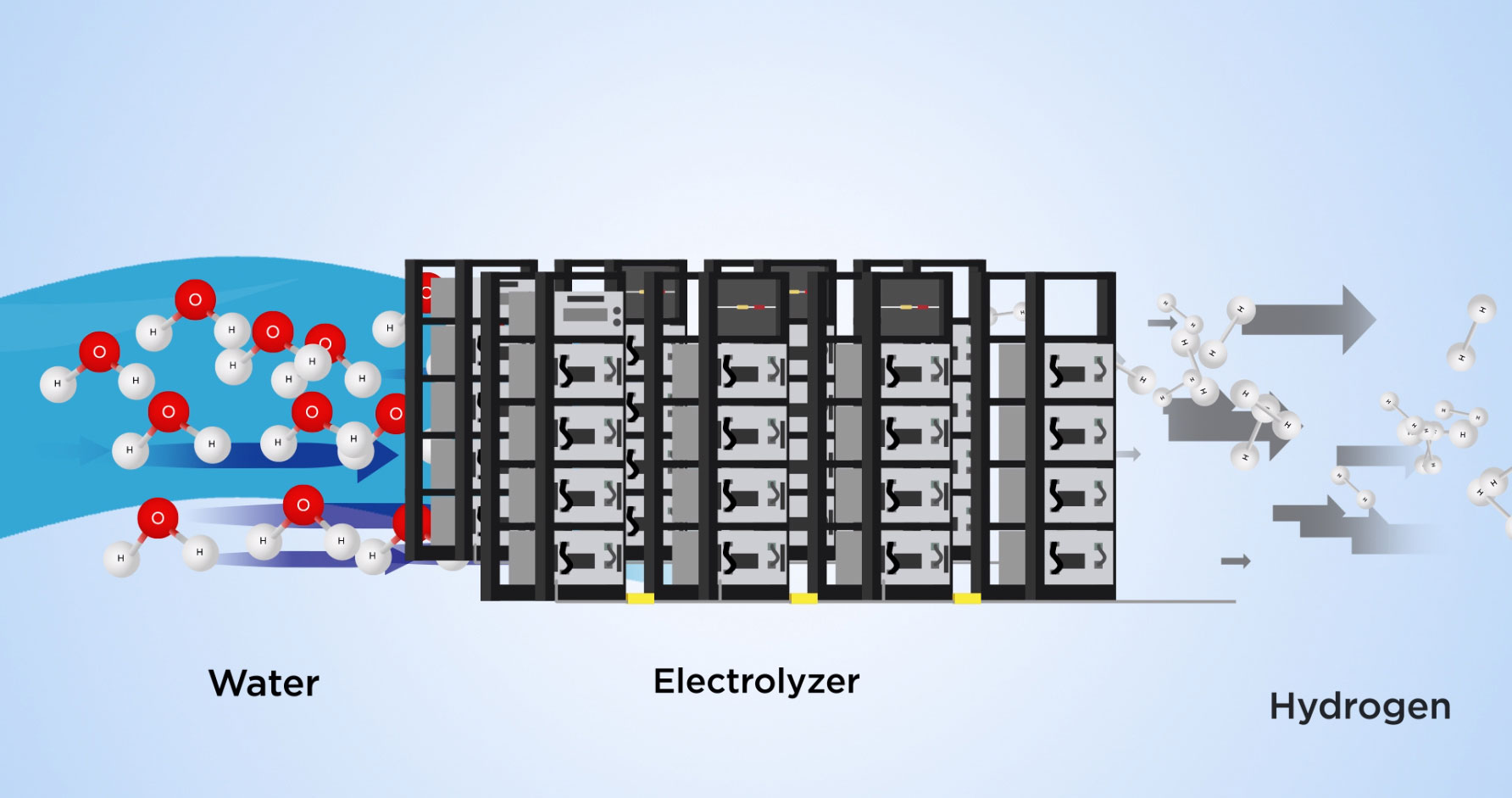

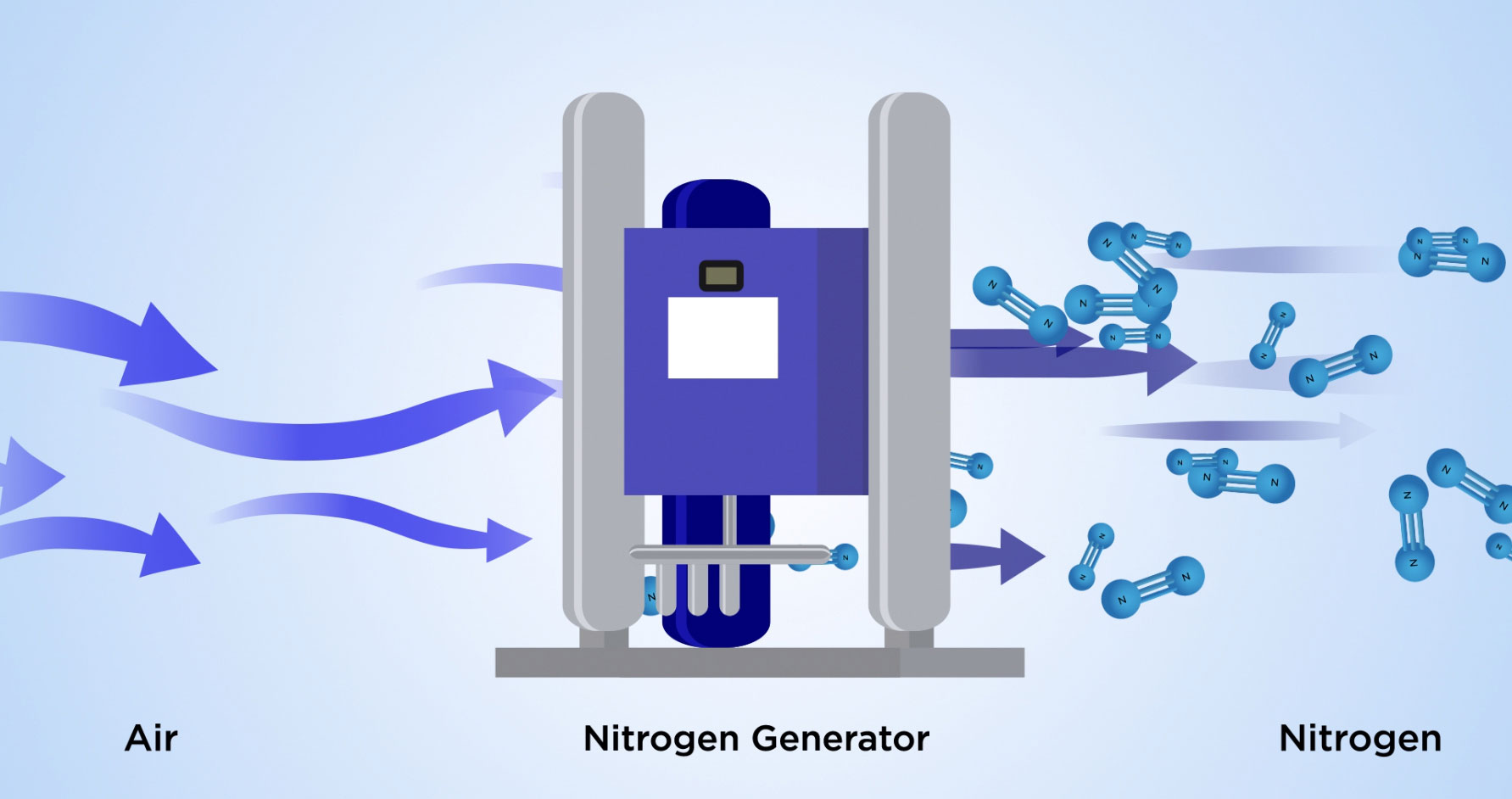

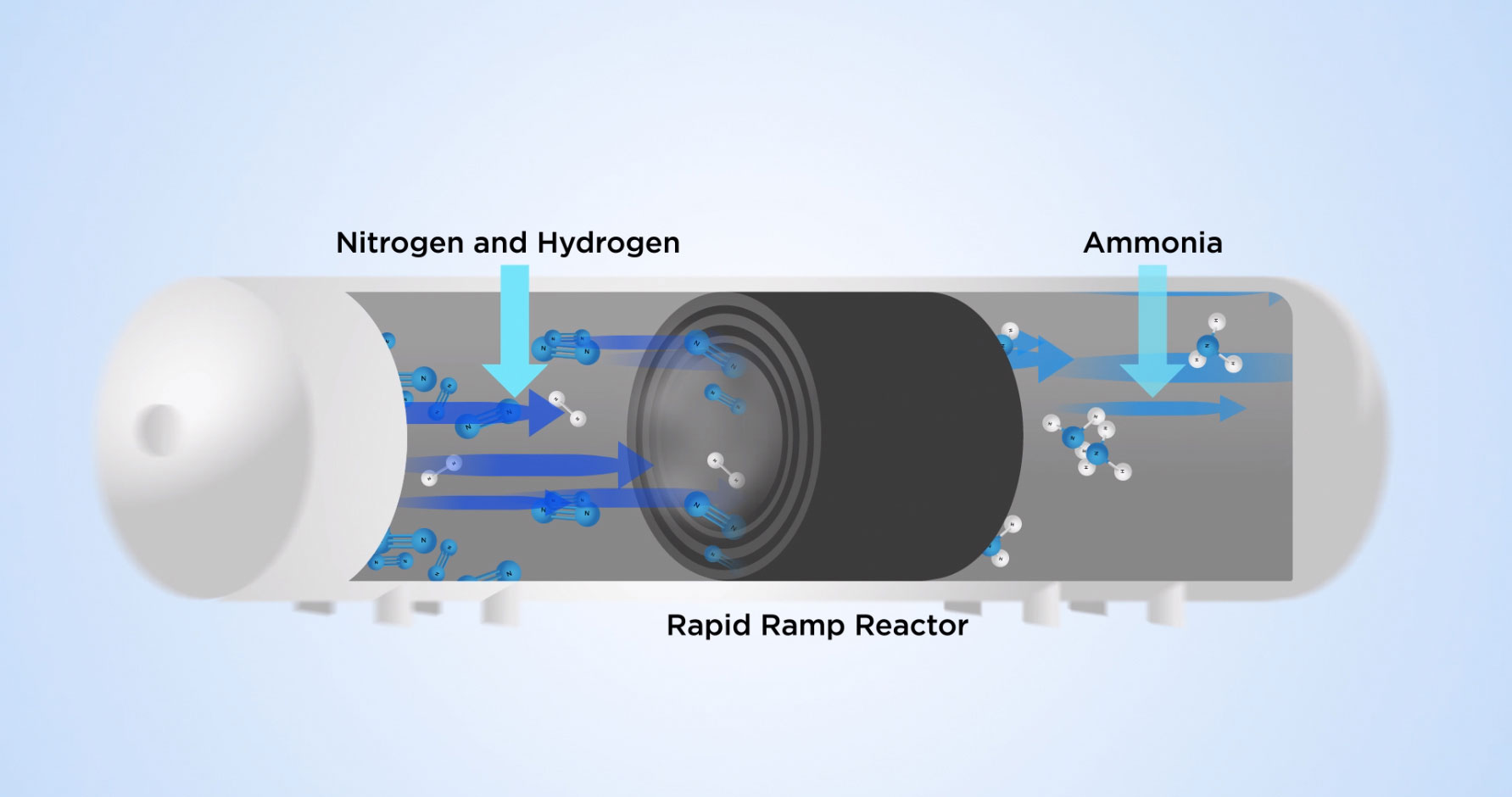

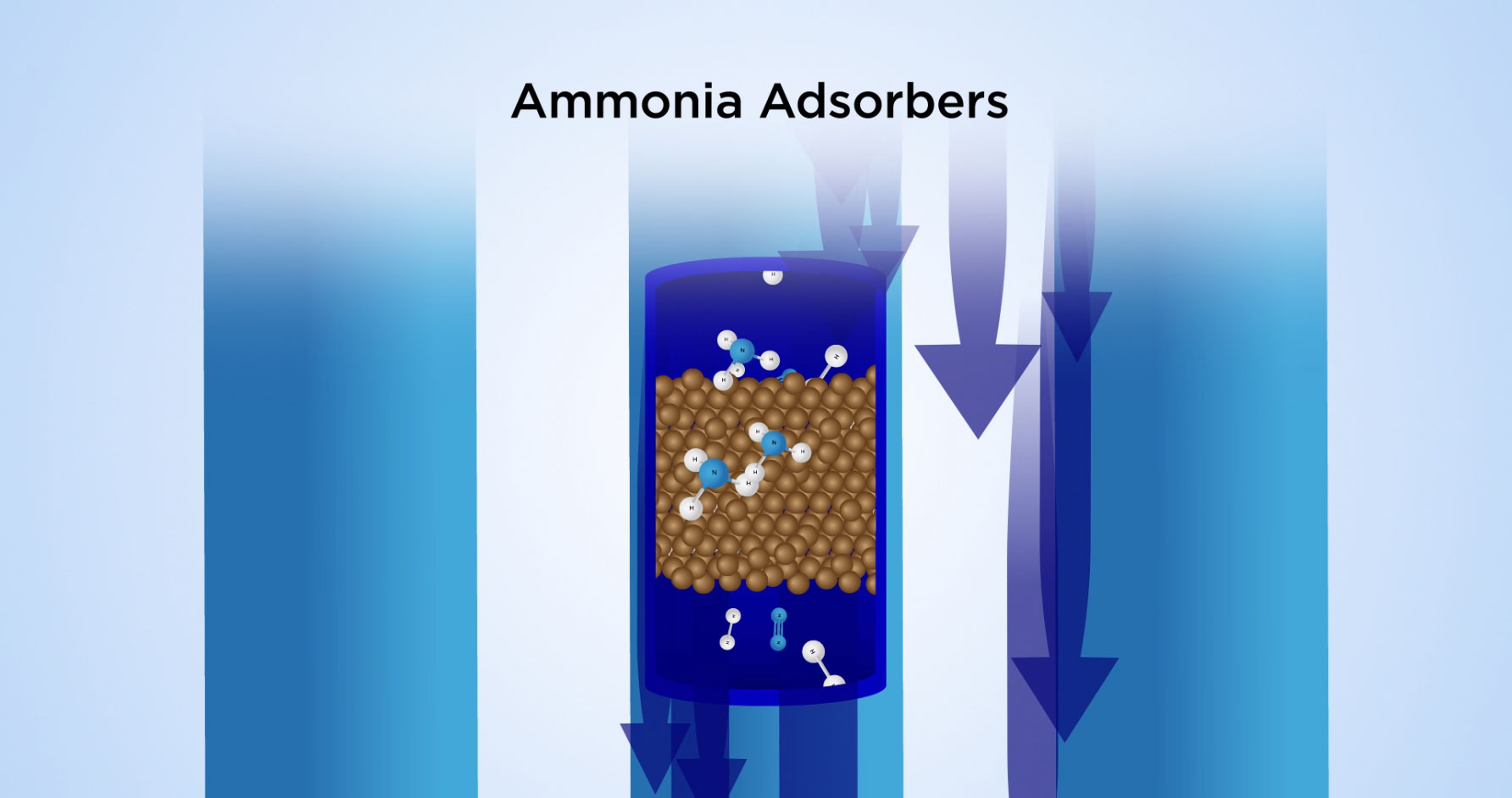

Starfire Energy is commercializing modular green ammonia systems. Unlike traditional Haber-Bosch designs our RapidRamp process can accommodate being directly powered by intermittent energy sources such as wind, solar, and hydro electricity.

Our process can scale back to a zero capacity factor and rapidly scale right back to 100% or anywhere in between. This allows for the synthesis of documentably 100% green ammonia.

The plants are built in modular shipping containers which are pre-wired and pre-plumbed for easy interconnection on site. These modules are produced in a mass production factory setting creating economies of scale along with predictable costs and plant commissioning times.

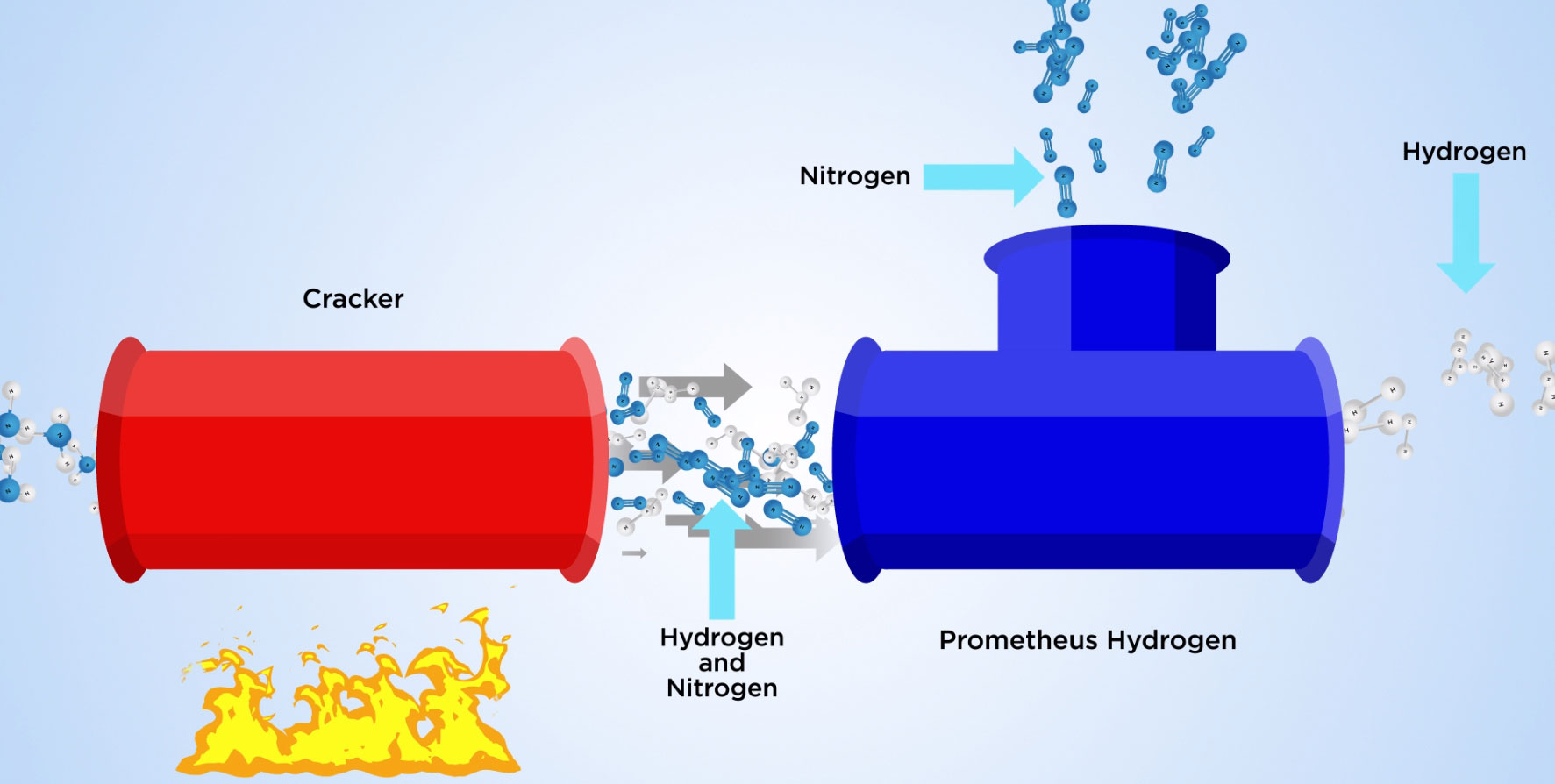

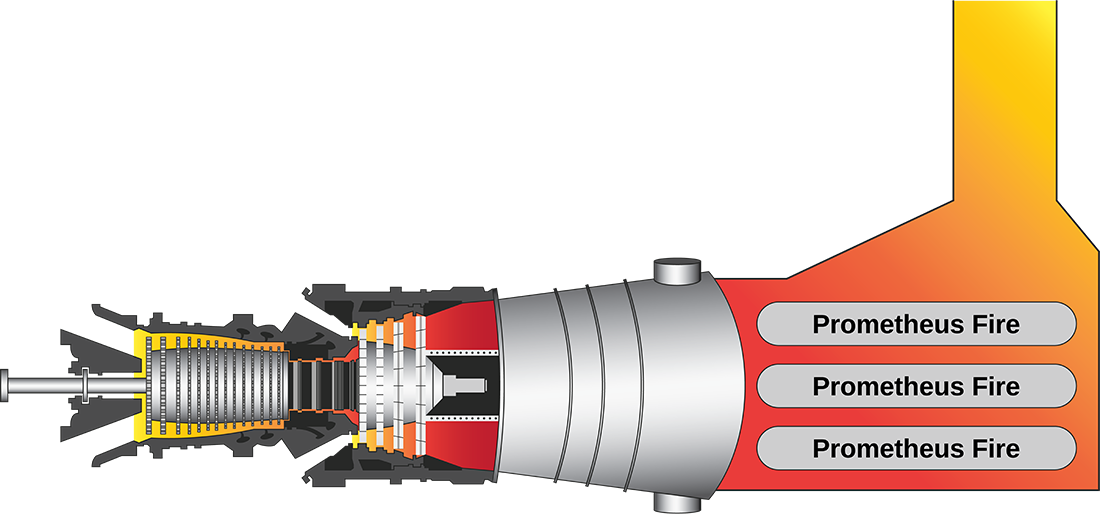

Prometheus Fire

Starfire is addressing ammonia fuel use by developing a cracking system that converts ammonia into nitrogen and hydrogen. The cracked ammonia can be used in a wide range of equipment.

Prometheus Hydrogen

Prometheus Hydrogen is being developed to crack ammonia back to nitrogen and hydrogen for fuel cell applications.